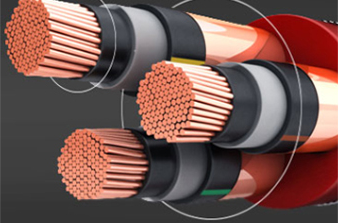

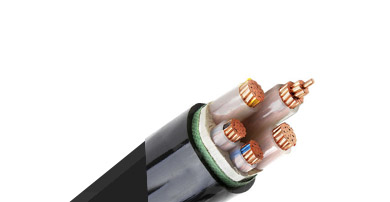

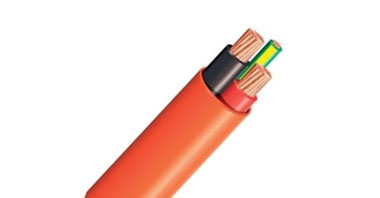

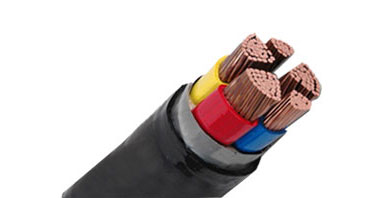

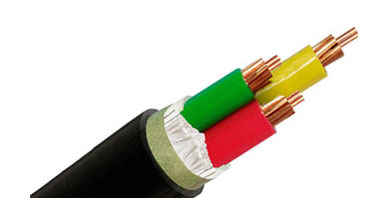

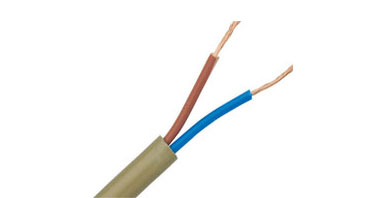

XLPE insulated cable(also called XLPE insulated wire) features a plain annealed twisted and sold circular copper conductor with XLPE insulation and PVC out sheath, we supply a full range of low voltage 0.6/1kv from one core to five cores. The cross linked polyethylene insulated cable/wire is widely used in the net power systems and power distribution and transmitting. We can make the XLPE insulated power cable according to IEC 60502, BS 7889 and AS/NZS 5000.

Jenuin, one of the leading XLPE cable manufacturers, is dedicated to providing high quality and cost-effective XLPE insulated power cable for clients, feel free to contact us!

English

English  français

français  Deutsch

Deutsch  العربية

العربية  tiếng việt

tiếng việt  ไทย

ไทย  čeština

čeština  Indonesia

Indonesia  Eesti

Eesti  български

български  slovenčina

slovenčina

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+